Large-size valves are strategic components in industries where fluids are handled on a large scale, under high pressure, or in extreme conditions. Their use is not only a functional requirement but also a matter of safety, energy efficiency, and operational reliability.

In this article, we analyze the main industrial sectors that require large-diameter valves and why the machining of these components must meet strict technical standards.

Why do some industries require large-size valves?

- Higher flow rates: Large-diameter valves are needed to handle high volumes of fluids or gases.

- Extreme conditions: Pressure, temperature, or aggressive substances demand robust and precise components.

- Critical processes: A valve failure can halt strategic operations or compromise safety.

🛢️ 1. Oil & Gas

In both upstream and downstream operations, these valves control the flow of oil, gas, or vapors under pressure. They are used in pipelines, refineries, pumping stations, and loading terminals.

🚢 2. Naval and Offshore

Large vessels, floating production storage and offloading units (FPSOs), and offshore platforms use large-size valves in cooling, ballast, propulsion, and discharge systems. These components must resist marine corrosion and be easy to maintain in remote environments.

🧪 3. Petrochemical Industry

Plants that process chemical products or natural gas require robust valves capable of withstanding aggressive substances, high temperatures, and continuous operation. Their design and machining must be adapted to the specific requirements of each process.

💧 4. Water Treatment

In water purification plants, wastewater treatment facilities, or large-scale irrigation systems, large-size valves ensure safe and efficient fluid flow. They are also essential in pumping stations and desalination plants.

❄️ 5. Cryogenics

Handling liquefied gases like oxygen, nitrogen, or helium requires large cryogenic valves that function precisely at extremely low temperatures. These valves must maintain thermal insulation and tight sealing.

⚡ 6. Power Generation

In thermal, hydroelectric, and combined-cycle power plants, large-size valves regulate the flow of steam, water, or gases in high-pressure systems. Their reliability is critical to avoiding unplanned shutdowns or accidents.

Why is the machining of these valves so critical?

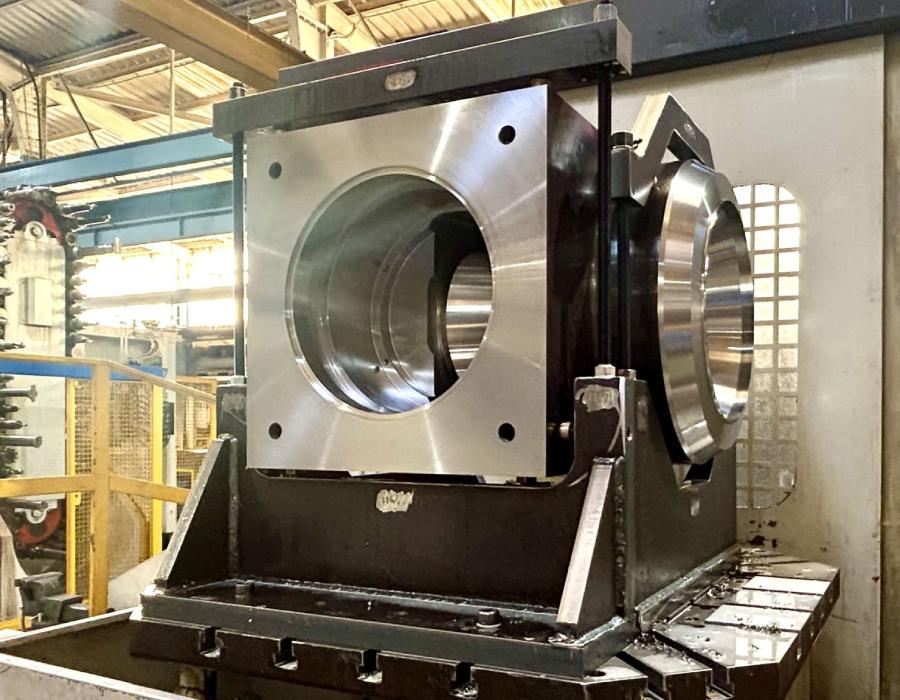

Each sector imposes specific technical requirements: tight tolerances, resistant materials, anti-corrosive coatings, leak-proof performance… That’s why, at Asimer Group, we apply precision CNC machining, specialized welding, and rigorous quality controls to ensure the reliability of every valve, regardless of the environment where it is used.

👉 Want to know how we machine large-size valves at Asimer Group? Read our technical article here:

Large-Size Valve Machining at Asimer Group

Key answers about the use and machining of large industrial valves

Which industries use large-size valves?

The sectors that most frequently use large-size valves include Oil & Gas, Naval, Petrochemical, Cryogenics, Water Treatment, and Power Generation.

Why does the machining of large valves require specialized processes?

Because they must withstand extreme conditions of pressure, temperature, and corrosion. They demand tight tolerances and high-quality welding.

What does Asimer Group offer in the machining of these valves?

Precision CNC machining, customization based on drawings or samples, specialized welding, and quality controls that ensure reliability in demanding sectors.

Key points to consider

The industries that rely on large-size valves operate in conditions where there is no room for error. The design, machining, and finishing of each valve must be tailored to their specific needs. Having a provider with expertise in specialized industrial machining makes all the difference in terms of safety, performance, and durability.