The valve is an essential component in a wide range of industrial applications. It is responsible for regulating the flow of liquids, gases, and other mediums in critical systems. However, to ensure its proper operation and safety in processes, rigorous testing is essential. This is especially relevant in the case of needle control valves, where precision and reliability are crucial in the industry.

The importance of valve testing lies in the safety and efficiency of the process, and CNC machining plays a vital role in the creation of high-quality valves. This process ensures that each valve is machined with precision, optimizing its performance and reliability.

In the intriguing universe of industrial valves, where precision and efficiency are like the pulsating heart, it is essential to understand how technology is turning every corner of our industry. Industry 4.0 and the CNC Machining Revolution are like a breath of fresh air that not only redefines the way we manufacture but also leaves its mark on the quality and performance of valves. Imagine a scenario where valve testing is more than simple processes; it is part of a revolution. In this context, the influence of Industry 4.0 and the CNC Machining Revolution emerges as a significant milestone, marking a shift towards excellence in the manufacturing and testing of these essential components that pulse at the heart of industrial engineering.

What does a valve consist of?

A valve is an application/product that controls the movement of a fluid or gas.It manages the direction and/or controls the flow of a fluid or gas by opening and closing one or more steps.

Valves play a vital role in most industries involving pipelines or other applications, including the cryogenic sector. In the cryogenic sector, cryogenic applications are used for the production and handling of gases at very low temperatures, and cryogenic valves are crucial for the proper functioning of equipment in this industry. In addition, other industrial sectors such as the Oil & Gas Sector, the Petrochemical Sector, the Naval Sector and the Desalination Sector also use industrial valves in their operations. These sectors recognize the importance of valves to control the flow of fluids in pipelines and ensure safe and efficient operation of systems. In the oil and gas sector, for example, valves play a key role in preventing leakage and improving tightness. For more information on how to prevent leaks and improve tightness thanks to fittings in the oil and gas sector, we invite you to read our article dedicated to this topic. Click here for the full article on “How to prevent leaks and improve tightness thanks to fittings in the oil and gas sector“.

What types of valves exist in the industrial market?

There are 6 different types of valves: Globe valves, gate valves, ball valves, butterfly valves, check valves and plug valves. Each valve has a different design depending on the characteristics of the application and also on the pressure. Therefore, different industries/sectors mean different valves.

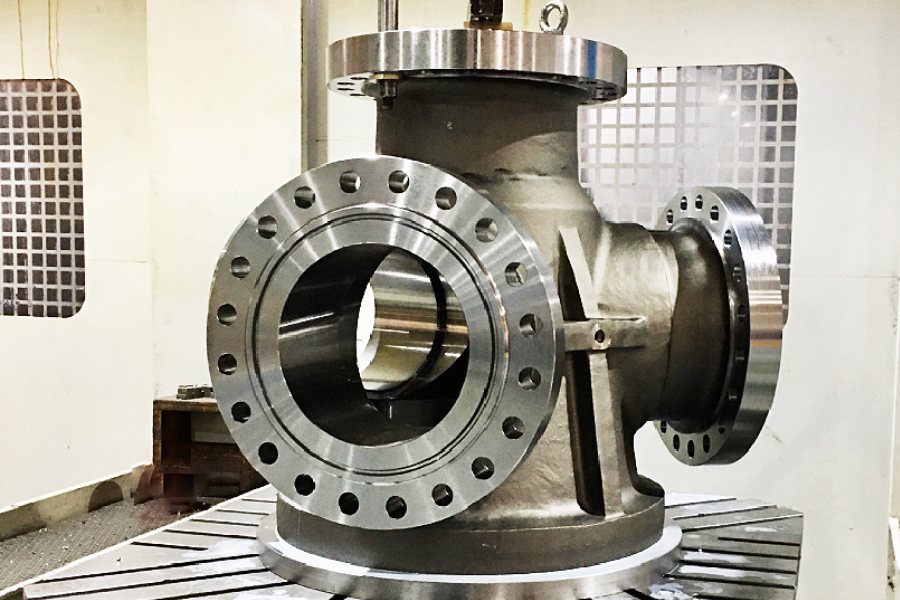

What are the main parts of a valve and how do they work?

Valves are the main elements of all piping systems and industrial equipment, as they allow control of the flow of liquids and gases. To understand the operation of the valves it is necessary to know the main parts that compose them and their role in the process.

- The valve body is the part containing the disc, which is the element responsible for regulating the flow of liquid. The body can have different shapes and sizes depending on the type of valve. The most common bodies are spherical, conical and cylindrical.

- A valve disc is a component that moves in the body and controls the flow of a liquid or gas. The disc is available in various shapes and materials depending on the type of valve and the specific application. For example, they can be flat discs, spherical, conical, butterfly and others. The disc moves through a rod that transmits the movement to the disc, either manually or by means of a drive.

- The valve cap seals the housing and prevents liquid leakage. The lid is available in different materials and shapes depending on the valve type and application.

Other important parts of the valve are the seat, which is the contact surface between the disc and the body, and the seals, which are the components responsible for ensuring tightness between the different parts of the valve.

Knowing the basic parts that compose them and their role in the process is important to ensure their proper functioning and ensure the efficiency and safety of the system in which they are used.

What types of valves are worked at Asimer Group?

The extensive experience of the Asimer Group focuses mainly on the following types of valves:

- Gate valves

- Globe valves

- Ball valves

- Check valve

- Plug valves

- Butterfly valves

- Axial valves

Why is a valve test important?

In the field of industrial valves, it is crucial that they operate reliably, safely, and accurately, ensuring they regulate the appropriate pressure without leaks at all times. There have been cases where high-pressure systems have experienced leaks and even explosions, resulting in failures and significant losses in the industrial plants where they are installed. Therefore, maintaining the integrity of valves in high-pressure systems is of paramount importance, both for safety and productivity reasons.

When we consider the importance of valves in the industry, it is essential to highlight how valve testing is fundamental to ensure their performance and reliability. In this process, collaboration with cutting-edge facilities like the Trevisan Machining Center becomes essential. These facilities are equipped with state-of-the-art technology that allows for precise calibration and maintenance of valves, contributing to optimal operation and the improvement of product quality.

We cannot overlook how energy efficiency in industrial valves is closely related to valve testing, and that’s why it is essential to consider it in the design of these devices. Energy efficiency tests play a crucial role in evaluating the performance of a valve, as they determine its operation in terms of energy consumption and pressure loss. Considering energy efficiency in valve design not only contributes to resource conservation and reduced operational costs but also ensures a more sustainable and cost-effective operation in industrial applications. Therefore, understanding the interrelationship between energy efficiency testing and valve testing is essential to ensure optimal performance and increased resource management effectiveness in the industry.

What does a maintenance and pressure test on valves consist of?

Valve tests are carried out as a maintenance process to assess the condition or health of an operating valve. The following ones, are the functions of a valve tests machine in a high pressure system:

- Valve leak tests

- Seat and seal test

- Seat leak inspection

- Suitability for fluid and gas testing

Valve tests are typically done to rectify problems such as mechanical friction, cavitation, plugged flow, erosion, and valve noise, among others.

The benefits of these valve pressure tests are that they are all automated, allowing them to create a record of all previous data. Additional features such as test benches, vacuum tests and customizable equipment are also provided according to requirements.

Why does a valve corrode and how to prevent its corrosion?

As the valves are constantly exposed to fluids (gasses and liquids, many of them toxic and/or abrasive), there is a high probability that the system (set of valves, pipes, connections, etc…) will begin to corrode. Other common problems that occur are that minerals build up to create leaks.

Valve corrosion is commonly considered as damage to the metallic material of the valve under the effect of a chemical or electrochemical environment. Since “corrosion” occurs in the spontaneous reaction between the metal and the surrounding environment, corrosion prevention focuses on how to separate the metal from the surrounding environment or use more synthetic non-metallic materials. Here we are going to list the different ways to prevent valve corrosion:

- Electrochemical protection

- Use of non-metallic material

- Metal surface treatment

- Choose corrosion-resistant materials according to the corrosive medium

- Spray coating

- Add corrosion inhibitors

- Thermal spray

- Control corrosive environment

- Improve processing technology and valve structure

Summarizing, we could say that electrochemical corrosion corrodes different types of metals. It acts between the two metals. Some metals are not resistant to corrosion, but they are capable of producing a very good protective film, that is, a passivation film that can prevent corrosion of the medium.

The most useful methods to prevent valve corrosion:

- Create a passivation film on the metal surface.

- Use non-metallic materials instead of metallic materials without electrochemical corrosion.

How often is valve pressure check required?

Depending on the pressure the valve is faced with, the ideal scenario would be that the tests were done eve