The specialized TIG welding applications in the manufacturing of pumps and industrial valves are crucial for ensuring the reliability and durability of these essential components in sectors such as naval, petrochemical, oil & gas, paper, cryogenics, desalination, and water treatment. At Asimer Group, we specialize in the machining and welding of pump and industrial valve components, using TIG welding to ensure high performance and resistance, tailoring our solutions to meet the specific demands of each industry. In demanding industrial applications, it is critical to understand the differences between TIG and MIG welding, especially when optimizing the strength and durability of pumps and valves exposed to extreme conditions.

Naval Industry: Resistance to Marine Environments

Specific Requirements

In the naval industry, pumps and valves must resist corrosion and withstand extreme pressures in marine environments. TIG welding is used to guarantee the quality and lifespan of these critical components for the operation of ships.

Applications in Pumps and Valves

- Centrifugal Pumps: Used for cooling and water transfer on ships. Corrosion resistance is key to preventing premature wear.

- Butterfly Valves: Commonly used in ballast systems, their high resistance to corrosion and precise flow control capability are vital for naval operations.

Success Stories at Asimer Group

At Asimer Group, we have worked on numerous projects requiring the welding of pump and valve components for cargo ships and vessels. Our expertise in TIG welding has ensured optimal performance in systems exposed to saltwater, reducing maintenance costs and enhancing durability.

Petrochemical and Oil & Gas Industry: Safety in Critical Operations

Specific Requirements

In the petrochemical and oil & gas industries, oil refining demands components like high-strength, durable pumps and valves. These are essential for the safe and efficient handling of fluids in extreme conditions, highlighting the importance of welding and machining in the manufacturing of these devices.

Applications in Pumps and Valves

- High-Pressure Centrifugal Pumps: Used to transfer fluids at high pressure in refineries and petrochemical plants.

- Ball Valves: Preferred for their ability to provide perfect sealing and ease of operation under extreme pressures.

Success Stories at Asimer Group

At Asimer Group, we have contributed to several petrochemical projects, machining and welding components for centrifugal pumps and ball valves, ensuring safe performance in critical environments. CNC technology ensures robust and durable components that meet the demands of corrosive environments and extreme pressures. Thanks to TIG welding, we have improved the resistance and longevity of these components, essential for continuous, fault-free operations. To ensure the quality and safety of our welds, at Asimer Group we perform non-destructive testing that verifies the integrity of the components without compromising their structure.

Cryogenic Industry: Low-Temperature Operations

Specific Requirements

Cryogenic applications in the aerospace industry are essential for developing technologies that operate at extremely low temperatures, ensuring the integrity and optimal functioning of complex systems in extreme conditions.

Cryogenic components, such as gate valves and pumps, require precise processes like machining large-scale valves to withstand extreme temperatures and ensure optimal performance.TIG welding ensures precise and defect-free joints that could compromise integrity under cryogenic conditions. Cryogenic valves are essential for providing a tight seal and reliable performance in systems operating at low temperatures, ensuring safety and efficiency in critical industrial applications.

Applications in Pumps and Valves

- Cryogenic Pumps for Liquefied Gases: Specialized in handling gases like liquid oxygen and nitrogen, requiring precise sealing and high-quality materials.

- Cryogenic Gate Valves: Ideal for applications demanding hermetic closure in low-temperature gas systems.

Success Stories at Asimer Group

We have worked on projects involving the welding of cryogenic valves and pumps, enhancing component resistance to thermal contraction and expansion, which is essential for safety and efficiency in the handling of liquefied gases.

Desalination and Water Treatment: Quality and Durability

Specific Requirements

Corrosion resistance and durability are essential in water treatment and desalination applications. Additionally, energy efficiency in industrial valves is crucial for reducing operating costs and improving sustainability in sectors like desalination and water treatment. In this context, TIG-welded pumps and valves not only ensure efficient and uninterrupted operation but also offer greater resistance to adverse conditions, prolonging their lifespan and minimizing maintenance.

Applications in Pumps and Valves

- Desalination Pumps: Move large volumes of seawater through reverse osmosis membranes, enduring high levels of corrosion.

- Control Valves: Used to regulate flow in treatment systems, they must maintain precise operation and corrosion resistance.

Success Stories at Asimer Group

Asimer Group has machined and welded valves and industrial pumps for desalination plants, increasing service life and optimizing the energy efficiency of water treatment systems. Our solutions ensure reliable and extended operation, even in highly corrosive conditions.

Applications of TIG Welding in Industrial Pumps

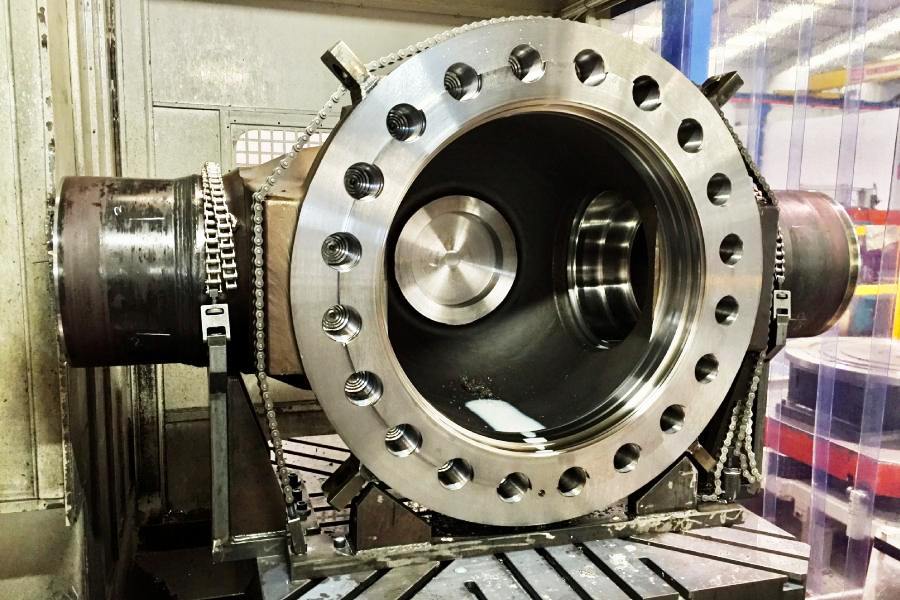

Centrifugal Pumps

At Asimer Group, we use TIG welding for the manufacturing of casings and impellers of centrifugal pumps. These components require high precision welding to ensure optimal performance and extended service life. The temperature control and penetration of TIG welding ensure that the casings and impellers can withstand the abrasive conditions and mechanical stress of continuous operation.

Dosing Pumps

Dosing pumps, essential in chemical and pharmaceutical processes, demand extreme precision in their construction. The integrity of TIG welds is particularly beneficial for the internal systems of these pumps, where even the slightest defect can cause dosing variations. The use of CNC machining tools in the manufacturing of these devices has enabled unprecedented levels of precision, optimizing both the quality and efficiency of the production process. Accuracy in CNC machining is crucial to ensure that industrial pumps and valves meet the quality and performance standards required in critical applications. Industry 4.0 and the CNC machining revolution are transforming the manufacturing of industrial pumps and valves, enabling unprecedented precision and optimizing TIG welding processes to ensure high-quality components.

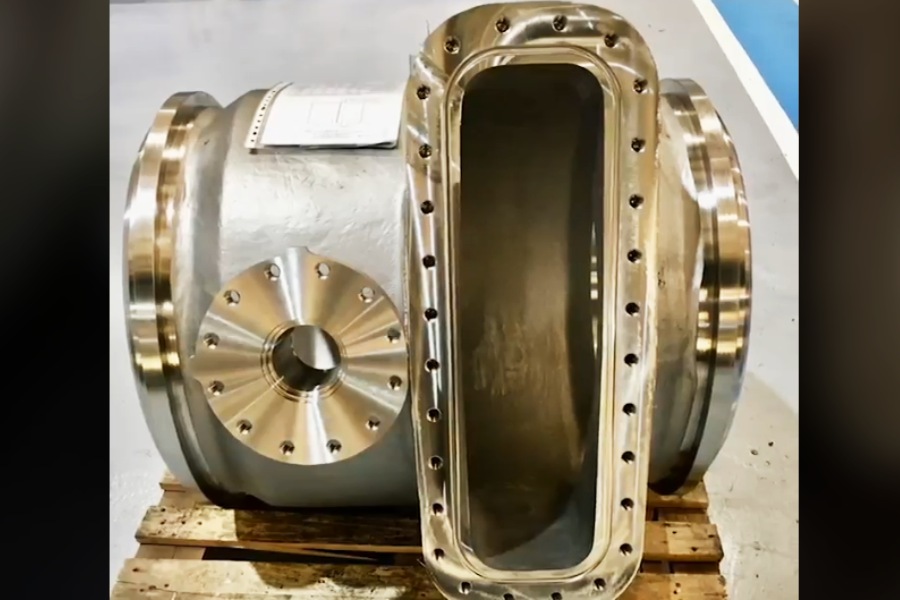

Vacuum Pumps

In vacuum pump manufacturing, TIG welding is used for both internal and external components, ensuring leak-proof construction. The specific properties of TIG welding ensure that vacuum pumps maintain their operational efficiency even under extreme vacuum conditions. The integration of chip removal machining ensures superior precision and quality in the creation of industrial components, complementing TIG welding to offer high durability and performance products.

Applications of TIG Welding in Industrial Valves

Check Valves

In critical industrial applications, axial flow check valves stand out for their ability to control the unidirectional flow of fluids with high efficiency and minimal pressure loss. These valves greatly benefit from the precise and robust welds provided by TIG welding, ensuring superior performance in demanding industrial environments. At Asimer Group, we apply this technique to ensure that our check valves operate efficiently without the risk of leaks or structural failures.

Additionally, technological innovations in the manufacturing of industrial valves have enhanced the precision, strength, and efficiency of these components.

Ball Valves

In ball valve manufacturing, TIG welding allows the creation of durable, defect-free joints, fundamental for the correct functioning and longevity of the valve. Ball valves are used across a variety of industries, including chemical, petrochemical, and water treatment, where weld quality is paramount.

Butterfly Valves

Butterfly valves, used in regulating fluid flow, require high-precision welding to ensure proper sealing and smooth operation. The ability of TIG welding to produce uniform, porosity-free weld beads is key to the performance of these valves.

Conclusion

Specialized TIG welding applications in the manufacturing of industrial pumps and valves are fundamental to ensuring high-quality, high-performance components in demanding sectors. At Asimer Group, our TIG welding solutions, combined with our machining and engineering solutions, ensure that each component meets the most rigorous industry standards.

If you are a manufacturer of industrial pumps and valves and are looking for an expert partner in welding and machining, Asimer Group is ready to provide innovative and reliable solutions. Contact us to discover how we can collaborate on the success of your next project.