The diaphragm valve is a versatile and reliable solution used in various industrial applications. Its unique design, composed of a flexible diaphragm and a sturdy body, makes it ideal for tackling the most demanding challenges in sectors such as oil and gas, pulp and paper, petrochemical, nuclear, cryogenics, desalination, and wastewater treatment.

In the oil and gas industry, these valves ensure precise control of corrosive and high-pressure fluid flows. In the pulp and paper industry, their resistance to chemicals and ability to prevent leaks are crucial for maintaining process efficiency. Furthermore, in the petrochemical industry, diaphragm valves offer excellent resistance to corrosion and high temperatures. In the nuclear field, their hermetic sealing capacity contributes to safety and control. Likewise, in cryogenic applications, these valves ensure the handling of gases and liquids at extremely low temperatures without compromising system integrity. In the field of desalination and wastewater treatment, diaphragm valves are essential for regulating flow and controlling chemical processes.

These types of valves stand out as a relevant and efficient option in the context of flow control valves and process efficiency.

Therefore, these valves, recognized for their innovative design and versatility, offer a series of features that make them indispensable in a wide range of industrial applications.

In this article, we will thoroughly explore the key characteristics of diaphragm valves and how they can enhance your pumping and fluid control systems. From their sturdy construction to their ability to handle corrosive and viscous fluids, these valves excel in durability and reliability in demanding industrial environments.

Additionally, we will examine the various applications where diaphragm valves are ideal, such as the chemical, pharmaceutical, food, and many other industries. With their ability to precisely regulate flow and prevent leaks, these valves adapt perfectly to the specific demands of each sector, ensuring optimal and safe performance.

What is a Diaphragm Valve?

Detailed Explanation of What a Diaphragm Valve Is and How It Works

When exploring the fascinating world of valves in the industry, it is essential to understand the basic concept of what a valve is and why conducting comprehensive tests is crucial. This prior knowledge will provide you with a solid foundation to delve into the topic of “Diaphragm Valve: Features and Applications in the Industry,” where we will explore in detail the outstanding characteristics of this versatile valve and its various industrial applications.

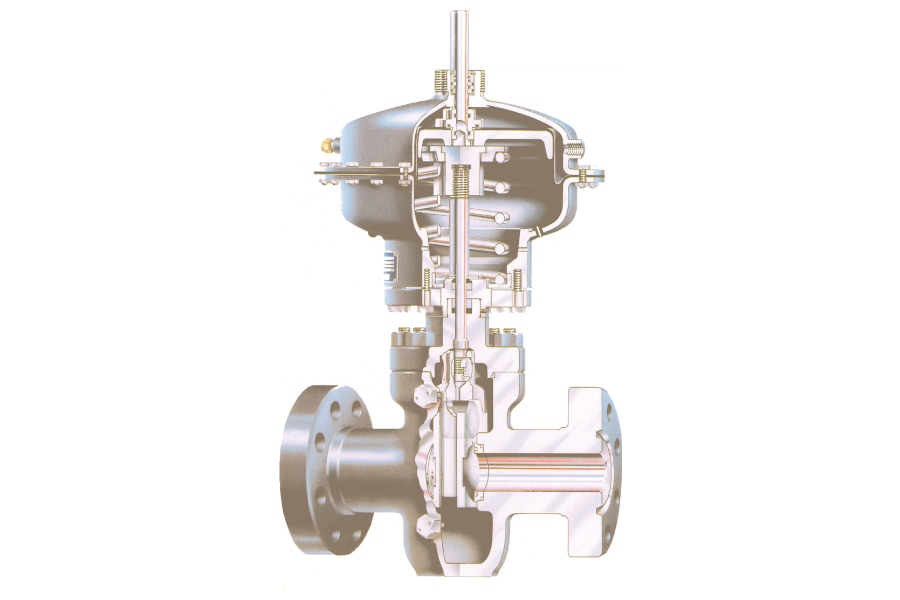

A diaphragm valve is an essential component in industrial systems that control the flow of liquids or gases. It consists of a flexible diaphragm that moves up and down to regulate the opening and closing of the flow. When the valve is closed, the diaphragm hermetically seals the passage of the fluid. By applying pressure to the diaphragm, it opens, allowing the fluid to pass through. Its design prevents leaks and allows for the handling of corrosive and viscous fluids. This makes diaphragm valves ideal for a wide range of industrial applications.

Description of the Main Components of a Diaphragm Valve

The main components of a diaphragm valve include a valve body, a diaphragm, an actuator, and a bonnet.

- The valve body houses the diaphragm and provides a connection for the fluid flow.

- The diaphragm, made of flexible and resistant material, moves up and down to regulate the flow.

- The actuator, which can be manual or automatic, controls the movement of the diaphragm.

- The bonnet is used to seal the assembly and ensure a tight closure.

These components work together to provide precise and reliable flow control in various industrial applications.

Characteristics of Diaphragm Valves

Diaphragm valves are characterized by their quality, efficiency, and durability in a compact and lightweight design. These valves are built with high-quality materials such as stainless steel and resistant elastomers, guaranteeing their corrosion resistance and high-temperature resistance. Thanks to their flexible diaphragm, diaphragm valves achieve a tight seal, preventing leaks and ensuring precise flow control. Their compact and lightweight design makes them ideal for installations where space is limited.

Advantages of Diaphragm Valves in the Industry

Diaphragm valves stand out for their ability to provide precise and reliable control of liquid and gas flows, allowing for accurate regulation in critical applications. One of their main advantages is their ability to handle viscous or corrosive substances, making them an ideal choice for demanding industrial environments where chemical resistance is crucial. Furthermore, their robust and durable design allows them to withstand high temperatures and pressures, ensuring optimal performance in adverse conditions.

Another significant advantage of diaphragm valves is their ease of maintenance and diaphragm replacement. The diaphragm, made of high-quality elastomeric materials, is a key part of the valve and can be easily replaced when necessary, without requiring the complete uninstallation of the valve. This significantly reduces downtime and maintenance costs, resulting in increased efficiency and productivity in industrial processes.

Additionally, diaphragm valves are characterized by their compact and lightweight design, making them especially suitable for applications where space is limited. Their reduced size does not compromise their performance, as they continue to offer precise and reliable flow control. This facilitates their integration into existing systems and installation in confined spaces.

It is essential to emphasize the close relationship between energy efficiency in industrial valves and the characteristics of diaphragm valves, as well as their importance in various industrial applications. Diaphragm valves stand out for their ability to provide a tight seal and precise flow control, making them essential in applications where energy efficiency is crucial. These valves enable precise regulation and minimal pressure loss, which not only saves energy but also contributes to more sustainable operation in industrial processes. Therefore, understanding and applying energy efficiency principles in diaphragm valves become a determining factor in improving the effectiveness and profitability of various industrial operations.

Applications of Diaphragm Valves in the Industry

Applications in Machining

In the vast world of industrial valves, it is crucial to understand the different types of valves available and their diverse applications in the industry. Diaphragm valves play a fundamental role in machining, where they are used to control the flow of liquids and ensure optimal performance in various applications. One of their key applications is the control of coolants and lubricants in machine tools. These valves allow for precise regulation of the amount of liquid supplied, ensuring proper cooling and lubrication to keep tools and parts in optimal condition.

Furthermore, in cutting and grinding systems, diaphragm valves are used to regulate the flow of liquids. This allows for precise control during the process, avoiding excessive or insufficient liquid, which in turn guarantees quality and precision in machining.

Applications in Welding

In welding, diaphragm valves find specific applications to ensure an efficient and safe process. One of these applications is the control of shielding gases in arc welding processes. Diaphragm valves allow for regulation of the amount of shielding gas supplied, creating an optimal environment for the welding process and ensuring the integrity of the welded joints.

Similarly, in cooling systems used in welding, diaphragm valves are employed to regulate the flow of coolants. This helps maintain an appropriate temperature during the process, preventing overheating and ensuring the durability of the equipment involved.

TIG welding stands out as the cutting-edge solution for manufacturing industrial pumps and valves, offering exceptional precision and quality in metal joining. Although not directly applicable to the construction of diaphragm valves, its use in producing other components is crucial for ensuring the structural integrity of the systems they contain. TIG welding ensures a precise and durable bond between the various elements composing these systems, contributing to their operational efficiency and safety. Moreover, being capable of working with a wide variety of materials, TIG welding enables the fabrication of robust and resistant components, meeting the demanding quality standards required in the diaphragm valve industry.

Engineering Solutions with Diaphragm Valves

Diaphragm valves offer customized engineering solutions for a wide variety of industrial applications. Their versatility and adaptability make them an ideal choice for designing and manufacturing tailor-made fluid control systems. These customized solutions ensure optimal performance by meeting the specific requirements of each project.

Furthermore, diaphragm valves integrate efficiently into complex industrial projects. Their compact design and ability to handle corrosive or viscous fluids make them a reliable choice for various industrial applications. Whether in the chemical, food, pharmaceutical, or any other sector, diaphragm valves perfectly adapt to the needs of the most demanding projects.

Diaphragm valves are a highly reliable device for obtaining customized engineering solutions that meet your specific requirements. Their ability to precisely control the flow of liquids and gases and their integration into complex industrial projects guarantee efficient and reliable operation in a wide range of industrial applications.

Diaphragm Valves at Asimer Group

In the context of Industry 4.0 and the CNC Machining Revolution, the diaphragm valve emerges as an innovative and highly efficient solution for a variety of industrial applications. The integration of advanced manufacturing technologies, such as CNC machining, enables the precise and customized production of diaphragm valves that meet the highest standards of quality and performance.

At the forefront of innovation and technical excellence, Asimer Group stands as a leading company in machining, welding of industrial valves, and customized engineering solutions. In our ongoing pursuit to provide cutting-edge services, we recognize the strategic importance of diaphragm valves in today’s industry.

- Commitment to Quality: Our team of experts in machining and welding actively engages in projects related to diaphragm valves, ensuring not only the highest quality but also outstanding performance in every delivered product. A deep understanding of the specific needs of our clients in various industrial sectors enables us to offer personalized solutions that adapt to their requirements and unique challenges.

- Versatility in Applications: The remarkable resistance to corrosion, hermetic sealing, and the ability to handle fluids with solid particles in suspension make the diaphragm valve an ideal choice for demanding applications. Its relevance extends to sectors such as the chemical industry, pharmaceuticals, and food and beverages, demonstrating its versatility and ability to overcome specific challenges.

At Asimer Group, the passion for excellence and the commitment to customer satisfaction are constant driving forces that propel us to exceed expectations in every project. We collaborate closely with our clients, understanding their goals and challenges, to deliver comprehensive engineering solutions that optimize the efficiency and performance of their systems.

- Leaders in Machining and Welding: If you are looking for reliable machining and welding services, Asimer Group is your ideal partner. We take pride not only in providing innovative and customized engineering solutions, backed by our expertise and technical knowledge but also in staying at the forefront of the industry through constant updates and continuous improvements. Trust us to take your projects to the next level.