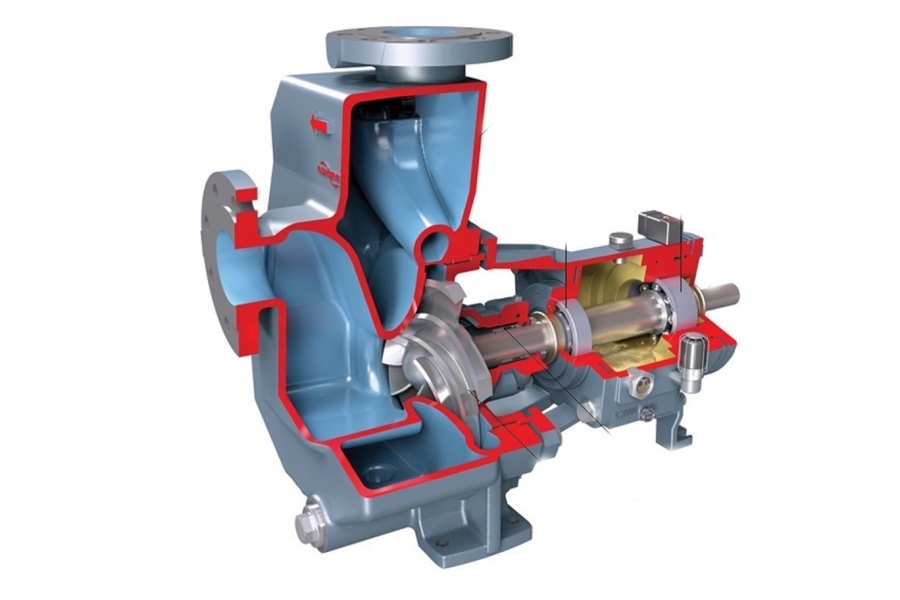

Understanding the components of a centrifugal pump is essential for a comprehensive grasp of how these industrial pumps function and their significance in engineering and industry. Centrifugal pumps play a crucial role in a variety of industrial applications, ranging from handling liquids to transferring fluids in chemical processes. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse sectors such as oil & gas, naval, pulp and paper, petrochemical, nuclear, cryogenics, desalination, and water and wastewater management.

Impeller

The impeller is the heart of a centrifugal pump. It is located within the pump casing and connected to the shaft. Its primary function is to increase the velocity of the liquid, creating centrifugal force. Impellers come in various shapes and sizes, and their design influences the efficiency and performance of the pump. This diversity of impellers renders them valuable in industries as varied as petrochemicals and wastewater management.

Types of Impellers

Several types of impellers are used in centrifugal pumps, including:

- Open Impeller: This type of impeller features uncovered blades on the sides, making it ideal for handling liquids with suspended solids. It is common in wastewater and sludge applications.

- Semi-Open Impeller: The semi-open impeller has partially covered blades, making it suitable for viscous and corrosive liquids. It is common in chemical applications.

- Closed Impeller: This impeller has fully covered blades and is efficient for handling clean and non-abrasive liquids, such as potable water.

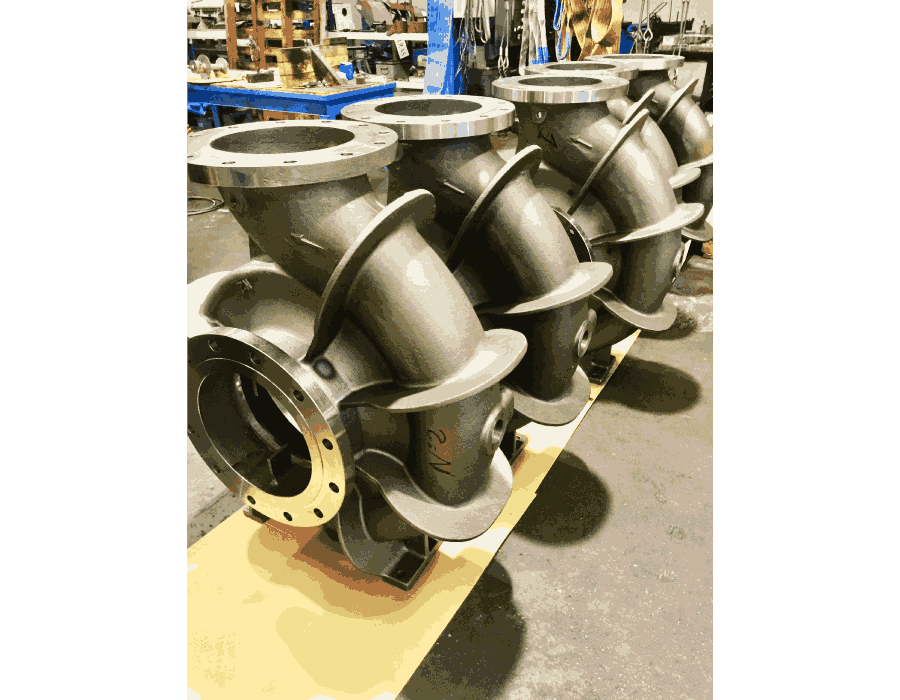

Casing

The casing surrounds the impeller and the pumped liquid. It has a specific shape that guides the flow of the liquid as it exits the impeller. The casing’s geometry is crucial for pump efficiency and can be of the volute or diffuser type, depending on applications in sectors like nuclear or desalination.

Types of Casings

Casings can have different configurations, such as:

- Single-Stage Casing: Used for applications requiring moderate pressure increase.

- Multi-Stage Casing: Used for applications requiring a significant pressure boost. These pumps have multiple impellers and casings in series.

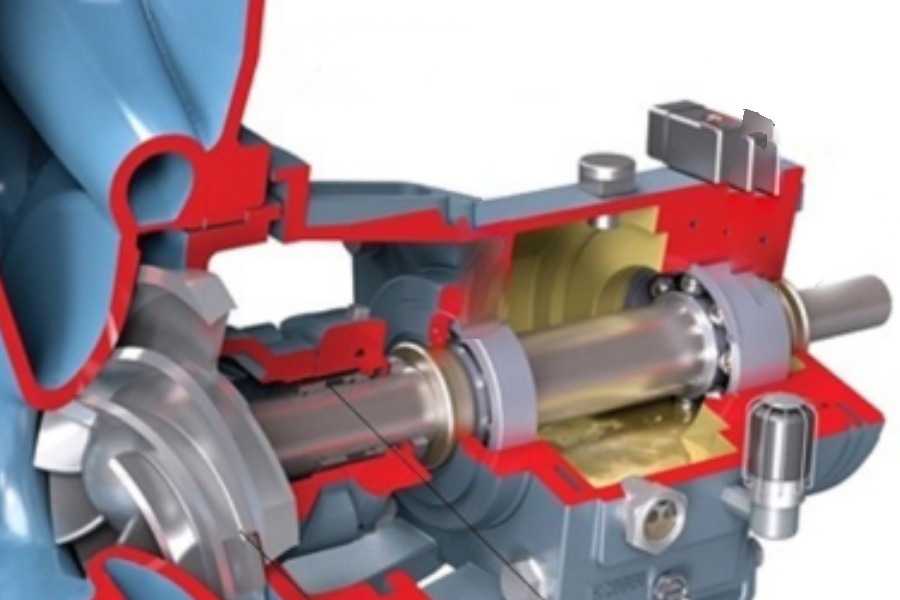

Shaft

The shaft connects the motor to the pump and transmits energy from the motor to the impeller. It must be robust and well-aligned to ensure smooth pump operation. Seals and bearings are used to support and seal the shaft in critical applications such as cryogenics.

Shaft Seal

The shaft seal is a vital component for preventing liquid leaks from inside the pump to the exterior. It is located at the interface between the shaft and the casing. Shaft seals can come in different types, such as mechanical seals or gland packing seals, and they are essential in industries like pulp and paper. The choice of shaft seal depends on the application and the type of liquid being handled.

Bearing

The bearing is an essential component in a centrifugal pump that plays a critical role in supporting and ensuring the smooth operation of the shaft, especially in applications in the oil & gas industry. Although often overlooked, its importance is fundamental in ensuring pump efficiency and durability. Below, we detail the function and relevance of bearings in the context of a centrifugal pump.

Bearing Function

Bearings in a centrifugal pump have two main functions:

- Shaft Support: Bearings support and align the pump’s shaft. This allows the shaft to rotate smoothly and efficiently, transmitting power from the motor to the impeller without excessive friction. Properly supported shafts are essential to prevent premature wear and unwanted vibrations.

- Friction Reduction: Bearings minimize friction between the shaft and bearing surfaces. This reduces energy dissipated as heat and enhances the overall efficiency of the centrifugal pump.

Types of Bearings

Several types of bearings are used in centrifugal pumps, including:

- Ball Bearings: Used when low friction and high precision are required. They are ideal for applications demanding high rotational speeds.

- Roller Bearings: Suitable for heavy-duty applications with high wear resistance.

- Sleeve Bearings: Used in applications where extreme loads and low rotational speeds are required.

Bearing Maintenance

Proper bearing maintenance is essential to ensure optimal performance of the centrifugal pump. This includes adequate lubrication, periodic wear inspection, and timely replacement of worn bearings.

Motor

The motor provides the necessary power to operate the centrifugal pump. It can be electric or of another type, depending on the application and environmental conditions. Motor power and control are crucial factors in pump operation in the maritime industry.

Base or Support

The base or support of the pump is the structure that holds the pump and motor in place. It must be sturdy enough to support the weight of the pump and withstand vibrations and forces generated during operation, especially in oil & gas-related applications.

Inlet and Outlet Valves

Inlet and outlet valves control the flow of liquid into and out of the pump. These valves are essential for regulating pump operation and preventing overloads or pressure loss, which is vital in water treatment applications.

Instrumentation and Controls

Depending on the application, centrifugal pumps may be equipped with additional instrumentation and controls, such as pressure sensors, flow meters, and automatic control systems. These devices help monitor and adjust pump performance as needed in sectors like petrochemicals and oil & gas.

Centrifugal pumps are fundamental devices in numerous industries, and understanding their key components is essential for their efficient maintenance and operation across a variety of fields, including nuclear power, oil refining, and the pulp and paper industry. From the impeller to the casing, shaft, and valves, each component plays a critical role in the overall functioning of the pump. Choosing the right components and regular maintenance are key to ensuring optimal performance and a long service life for these essential machines in the world of engineering and industry.

Asimer Group Experience

At Asimer Group, our extensive experience focuses on providing comprehensive solutions in the field of engineering, accuracy machining, and specialized welding, especially in the context of industrial valves and pumps. Our unwavering commitment to excellence and quality has positioned us as leaders in the industry.

- Custom Engineering Solutions

We understand that every project and industrial application is unique. Therefore, our highly trained team of engineers works closely with our clients to design customized solutions that meet their specific needs.

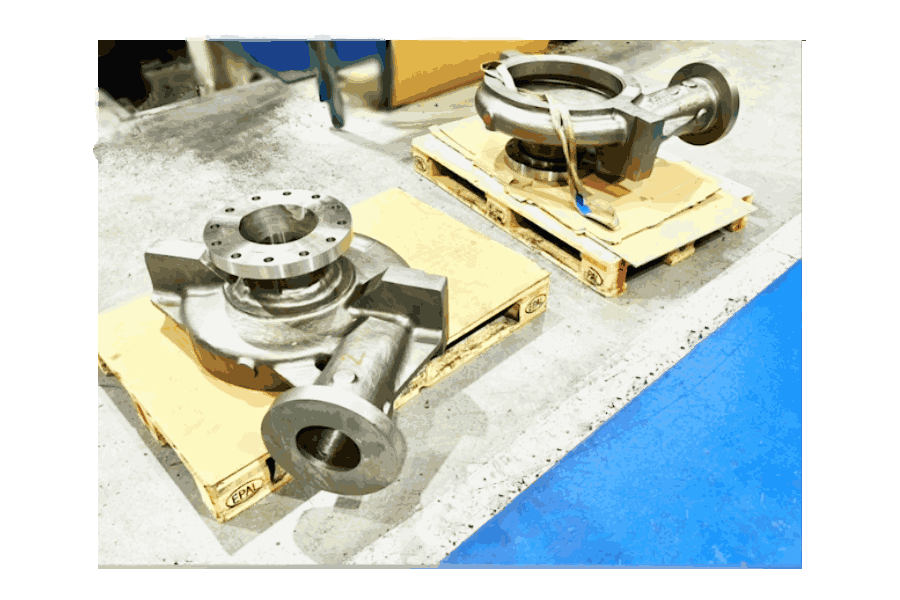

- Accuracy Machining

Precision is essential when it comes to critical components used in centrifugal pumps. Our state-of-the-art machining facility is equipped with the most advanced technology and operated by machining experts. This allows us to work with tight tolerances to ensure optimal performance of industrial pumps and valves. We take pride in offering precision machining that meets the industry’s most demanding standards.

- Specialized Welding

At Asimer Group, we have a team of highly skilled welders with experience in welding a wide range of materials, including stainless steels and special alloys. Our specialized welding ensures structural integrity and component strength, resulting in increased durability and reliable performance.

Accuracy is of utmost importance when it comes to crucial elements used in centrifugal pumps. Furthermore, to ensure the structural integrity and exceptional quality of our projects, we integrate TIG Welding: The Cutting-Edge Solution for Manufacturing Industrial Pumps and Valves. With this precision welding technique, we ensure the reliability and strength of critical components, meeting the industry’s most demanding standards.

- Commitment to Quality and Innovation

Quality is our top priority. All our products and services undergo rigorous quality controls to ensure they meet the highest industry standards. Furthermore, we constantly seek innovation and improvement in our solutions, utilizing the latest technologies and advanced practices to deliver exceptional results to our clients.

This commitment to quality and precision is exemplified by our state-of-the-art metrology room. Our metrology room serves as the cornerstone of our dedication to quality and precision in our projects for centrifugal pump components. Here, every piece undergoes rigorous testing and measurements to ensure it complies with the industry’s most demanding standards.

Precision in metrology is crucial to ensure that every square millimeter of our components falls within the exact tolerances required for optimal performance.

In addition, to support our commitment to precision, we employ advanced technologies such as a measuring arm, enabling us to perform precise measurements at every stage of the project.

- Your Partner in Industrial Success

We are not just a service provider; we are your partner in industrial success. We are here to face challenges with you and provide innovative, long-lasting solutions. By leveraging our expertise in engineering, machining, and welding, we help you achieve new levels of excellence in your operations.

Whether you require customized engineering solutions, precision machining, or specialized welding, Asimer Group is dedicated to delivering quality and reliability in every project. Our track record of excellence and commitment to innovation ensures that we are well-equipped to meet your industrial needs.

In conclusion, understanding the intricate components of a centrifugal pump is essential for comprehending its operation and maintenance in various industrial sectors. Asimer Group stands ready to be your trusted partner, offering tailored engineering solutions, precision machining, and specialized welding services to meet your specific requirements and contribute to your industrial success.