What is a Butterfly Valve?

Butterfly valve play a crucial role in the industrial field by regulating fluid flow in various processes. Their name comes from their characteristic design, resembling a butterfly with extended wings. However, the efficiency and precision of these valves heavily depend on the quality of their machining. In this regard, measurement and testing instruments, such as the measuring arm, become essential tools to ensure the dimensional accuracy of butterfly valves, ensuring a perfect fit and optimal performance. The measuring arm’s ability to capture and analyze real-time data, combined with its precision and versatility, allows manufacturers to obtain detailed information on tolerances and geometry during the machining process. By implementing these devices in industrial settings, higher production quality of butterfly valves is achieved, resulting in reliable and efficient performance across various industrial applications. These valves consist of a circular plate, known as the butterfly plate, that rotates on an axis within the valve body.

In the context of Industry 4.0 and the CNC Machining Revolution, butterfly valves have undergone significant transformation in manufacturing and industrial applications. The integration of advanced CNC machining technologies has enabled the production of butterfly valves with more precise designs, tight tolerances, and high-quality materials. Butterfly valves and their industrial applications stand out for their versatility and efficiency, essential in sectors such as water treatment, petrochemical industry, and HVAC systems.

Recent Innovations in Butterfly Valves

The evolution of butterfly valves continues with Industry 4.0. In recent years, new materials and coatings have been developed that significantly enhance corrosion resistance and wear resistance, increasing valve lifespan in aggressive environments. Furthermore, improvements in electric and pneumatic actuators have allowed for more precise control and increased automation in complex systems. These innovations not only optimize operational efficiency but also contribute to sustainability by reducing the need for frequent maintenance and replacement. Advances in sensors and monitoring technologies have also enabled the implementation of predictive maintenance systems, helping to prevent unexpected failures and maximize equipment uptime.

Butterfly valves, along with industrial pumps, are essential for ensuring efficient and precise flow control in various industrial systems.

The mechanism for opening and closing butterfly valves is based on the rotation of the butterfly plate. When the valve is closed, the plate is positioned perpendicular to the flow of liquid or gas, completely blocking passage. Rotating the plate allows flow as a circular opening is created between the plate and the valve body.

The angle of the butterfly plate is crucial for controlling flow through the valve. Increasing the plate’s rotation angle creates a wider opening, allowing for greater flow rate. Conversely, reducing the angle restricts flow, decreasing the flow rate.

This flow control mechanism is highly efficient due to low fluid resistance when the valve is fully open. The aerodynamic shape of the butterfly plate minimizes turbulence and pressure loss, resulting in smooth and efficient flow.

Butterfly valves are versatile and used in a wide range of industrial applications, from water supply systems and water treatment facilities to the chemical and petrochemical industries. Recognized as efficient flow control valves, butterfly valves stand out for their features and applications in the naval industry, where their compact design and precise regulation capabilities are essential for optimizing marine system performance. Their compact and lightweight design makes them ideal for applications where space and weight are critical.

However, in certain contexts, such as in piping systems with unidirectional flow, it is important to have a solution that provides flow control in a specific direction. This is where axial flow check valves come into play. These valves offer unique functionality that allows fluid flow in one direction and stops flow in the opposite direction, preventing unwanted backflow and ensuring system integrity. By combining the advantages of butterfly valves with the specific properties of axial flow check valves, industrial operators can achieve precise and reliable flow in a wide range of applications.

Components of Butterfly Valves

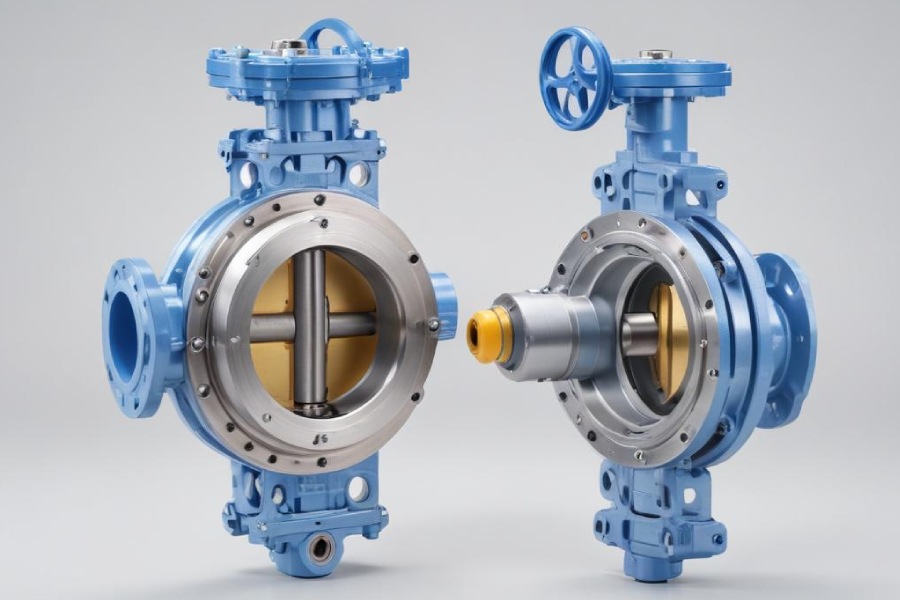

Butterfly valves are important devices in industrial piping systems and consist of several key components that ensure their proper operation. These components include the butterfly plate, stem, valve body, and seals.

- The butterfly plate is the central component of the valve. It is a circular disc that rotates around an axis within the valve body. Its main function is to control flow by opening or closing. When the plate is in the closed position, it completely blocks the circulation of liquid or gas. Rotating the plate creates an opening that allows fluid passage.

- The stem is a rod that connects to the butterfly plate and extends outward from the valve. Its main function is to transmit the rotational movement to open or close the valve. The stem is operated by a handwheel or lever, allowing the operator to control flow. It may also be equipped with a locking device to hold the valve position.

- The valve body is the main structure that contains all internal components. It is typically disc-shaped and designed to withstand fluid pressure and flow. Valve bodies are usually made from materials resistant to high temperatures and corrosion to ensure durability and operability.

- Seals are crucial elements in butterfly valves, ensuring proper sealing. There are various types of seals used in these valves, such as seat seals and stem seals. Seat seals are located in the valve body and ensure a tight seal when the plate is in the closed position. Stem seals are located on the stem and prevent leaks in the connection area.

Each component plays a fundamental role in the proper operation of the butterfly valve. The butterfly plate controls flow, the stem transmits movement, the valve body provides necessary structure and strength, and seals ensure proper sealing. The quality and proper design of these components are essential to ensure optimal performance and long service life of butterfly valves.

Advantages of Butterfly Valves

Compact and Lightweight Design

Butterfly valves are distinguished by their compact and lightweight design, providing significant advantages over other types of industrial valves. This design facilitates installation, maintenance, and operation of systems as they require less space and are easy to transport and handle. Additionally, their simplified structure reduces maintenance costs and allows easier access for inspection and repair. These advantages make butterfly valves a popular choice in many applications, enhancing the efficiency and functionality of the systems in which they are used.

When comparing butterfly valves to other types, such as diaphragm valves, it is crucial to understand the unique advantages they offer in terms of compact design and flow efficiency.

Efficient Flow Control

Butterfly valves provide efficient and quick flow control, thanks to their ability to adjust and regulate flow precisely. These valves allow for a rapid response to changes in system conditions, ensuring precise control of liquid and gas flow. Their design enables fast opening and closing, resulting in enhanced operational efficiency and optimal process control. With their ability to adjust and regulate flow precisely, butterfly valves are a reliable choice for a wide range of industrial applications.

Low Cost and Simple Maintenance

Butterfly valves stand out as an economical option in terms of initial costs and maintenance. Their simple design and robust components enable easy installation and straightforward maintenance. Additionally, their modular structure facilitates the replacement of individual parts without having to dismantle the entire system. These features reduce maintenance costs and make butterfly valves a cost-effective choice for industrial applications requiring efficient flow control without compromising on economy.

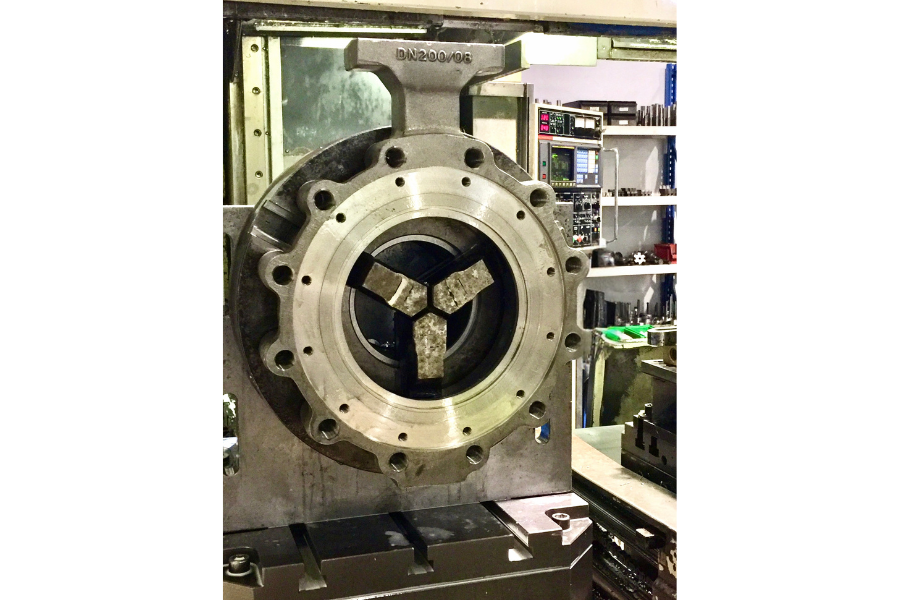

Butterfly Valves at Asimer Group

Asimer Group, a leader in machining and welding of industrial pumps and valves, offers cutting-edge solutions in the field of butterfly valves and their industrial applications. Our state-of-the-art technology enables us to participate in high-quality butterfly valve projects with precision and durability. Additionally, we have a team of highly skilled engineers who provide customized solutions to meet the specific needs of each client. Our machining centers ensure optimal performance, and our engineering focus allows us to create innovative and efficient solutions.