Trevisan Machining Center for Advanced Engineering Solutions: The Pillar of Success for Asimer Group.

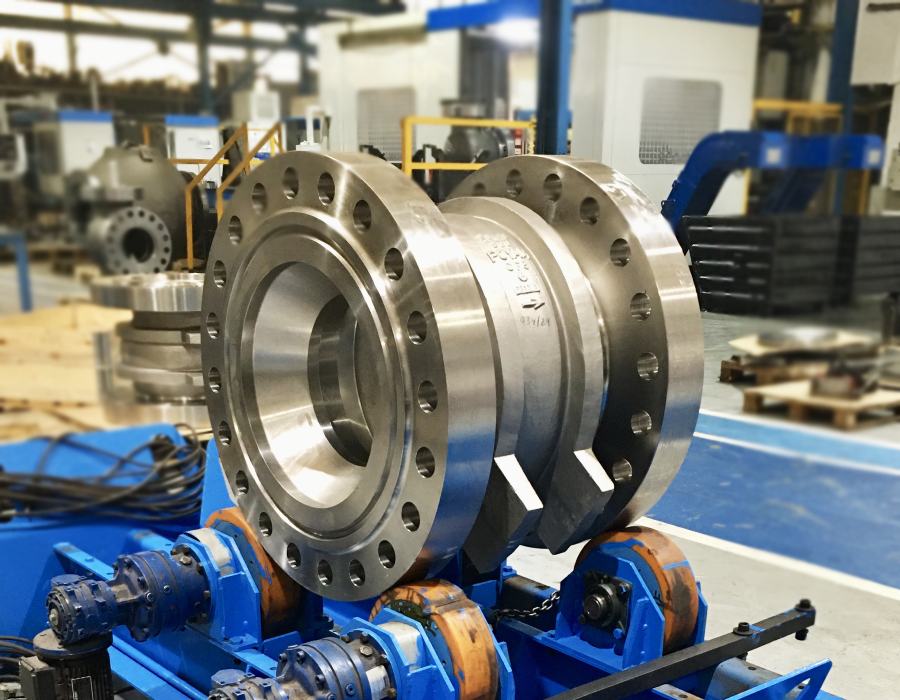

The Trevisan Machining Center has become an essential ally in our ongoing journey of improvement, emphasizing the importance of accuracy in CNC machining. In the exciting world of engineering and industrial manufacturing, the constant quest for improvements and efficiency has driven the development of advanced technologies. Asimer Group, a company dedicated to providing engineering solutions, …