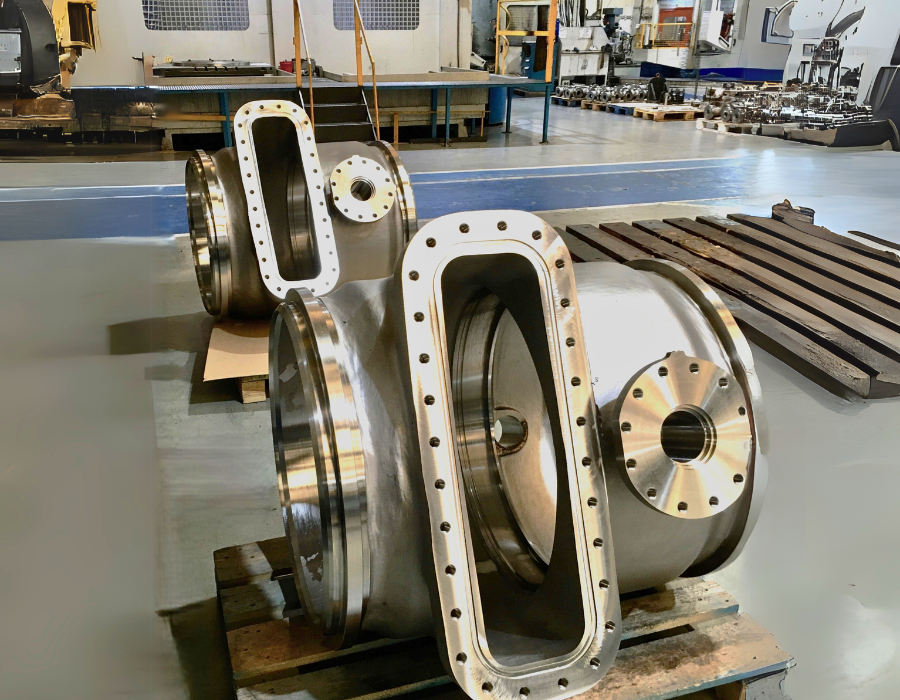

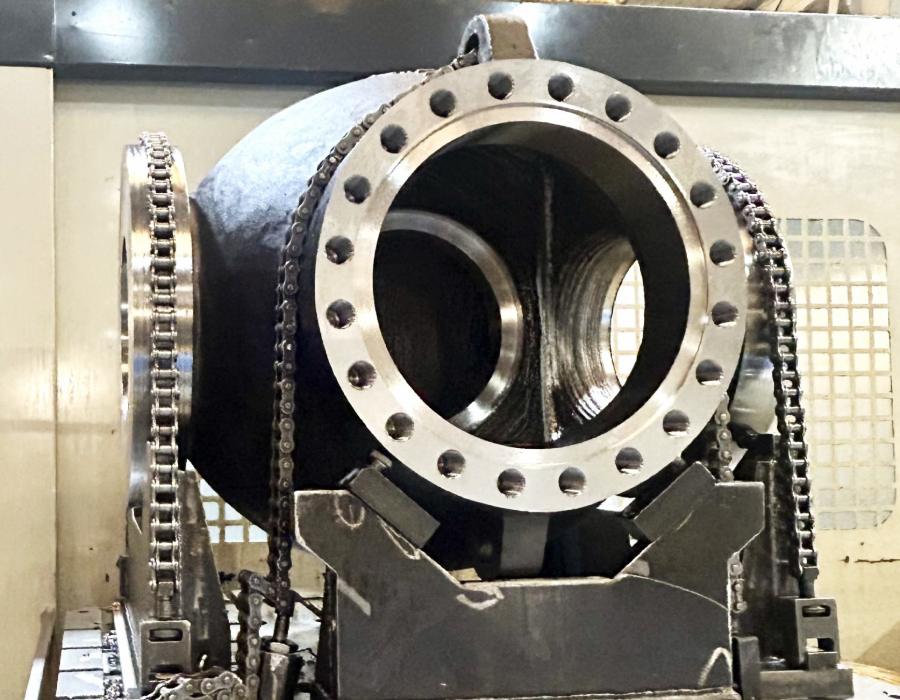

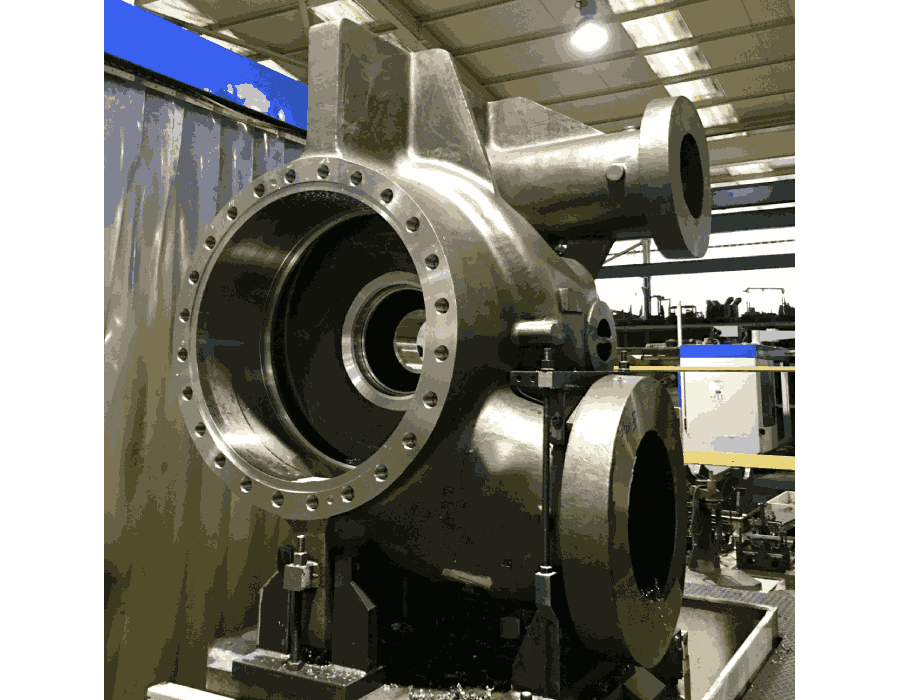

Machining of Stainless Steel Pumps and Valves

The machining of stainless steel pumps and valves is an essential process in the manufacturing of high-strength, durable industrial components. In sectors such as Oil & Gas, petrochemical, water treatment, and cryogenics, accuracy in CNC machining of these parts is key to ensuring their performance and reliability. At Asimer Group, we offer advanced CNC technology …