CNC machining tools, where every fraction of a millimeter matters, emerge as true artisans of precision and efficiency. In this article, we highlight the importance and impact of these advanced tools in the manufacturing of industrial valves and pumps, uncovering how they have become the key to achieving exceptional standards in the metallurgical industry.

We delve into the fascinating world of CNC machining, where skill merges with technology in The art of working metals with computerized control. Get ready to immerse yourself in a world where every cut, every detail, is perfected with precision through computerized control, redefining engineering standards and taking metallurgical excellence to new heights.

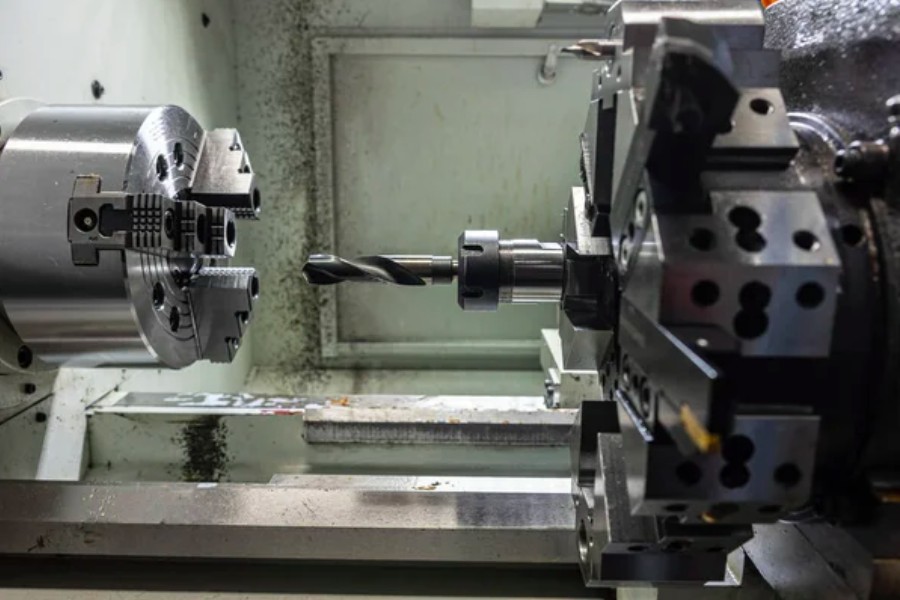

Traditional Machining Tools in Action

Drills: The Essence of Precise Drilling

Drills, fundamental in traditional machining, have long been the tool of choice for drilling and tapping. At Asimer Group, we recognize the importance of these tools in creating precise holes and preparing surfaces for subsequent processes.

Milling Cutters: Beyond Basic Cutting

Milling cutters, with their spaced blades, have played a crucial role in milling, slotting, and profiling in part manufacturing. Although more commonly associated with CNC machining, traditional milling cutters remain valuable in manual operations, adding versatility to projects undertaken by Asimer Group.

Saws: Cutting with Tradition and Precision

Saws, with their repetitive cutting action and friction, have been reliable companions in the task of cutting materials. At Asimer Group, traditional saws continue to play a crucial role, especially in operations where manual precision is essential.

The Revolution of CNC Machining Tools

Beyond Traditional Tools

In an era where precision is the currency, CNC machining tools have completely transformed the game of metallurgical manufacturing. Unlike traditional tools, these Computer Numerical Control (CNC) machines incorporate technology that allows millimeter precision and efficiency, redefining the boundaries of what is possible in the industry.

At the heart of the metallurgical industry, “Technological Innovations in Industrial Valve Manufacturing” are redefining the way key components are fabricated and processed. Explore how these new technologies are enhancing efficiency, precision, and quality in CNC machining tool production, driving excellence at every step of the process. With the advent of these innovations, limitless customization and millimeter precision are now the norm, taking industrial valve manufacturing to new heights of perfection and sophistication.

CNC Machining Tools in Action

CNC Mills: Sculpting Perfection

CNC mills, true masters of modern sculpture, play a crucial role in achieving tight tolerances and flawless surfaces. From casings to internal components of industrial pumps and valves, these tools not only ensure uniformity but also allow unprecedented customization.

CNC Lathes: The Dance of Versatility

The dance of CNC lathes becomes a symphony in the manufacturing of complex parts. At Asimer Group, we leverage the versatility of these machines to provide engineering solutions tailored to the specific needs of our clients. Whether in turning unique pieces or in large-scale production, precision remains constant.

Tangible Benefits of CNC Machining Tools

Redefined Efficiency

Efficiency is the hallmark of CNC machining tools. Compared to traditional methods, these tools drastically reduce production time. Asimer Group takes pride in implementing CNC technology to deliver products with faster delivery times and improved efficiency, a combination that resonates in customer satisfaction.

Millimeter Precision

Precision is the pillar of Asimer Group’s reputation. With CNC machining tools, we achieve millimeter precision crucial in the manufacturing of industrial pumps and valves. Each component is a masterpiece, carved with the accuracy of an experienced artisan.

Challenges Overcome with CNC Machining Tools

Limitless Customization

Customization becomes a reality thanks to the capabilities of CNC machining tools. In a world where adaptability is key, Asimer Group uses these tools to overcome manufacturing challenges, offering unique solutions tailored to the precise specifications of our clients.

Handling Complex Materials

The diversity of materials in the metallurgical industry presents unique challenges. Asimer Group’s CNC machining tools have proven their ability to handle complex materials, from conventional metals to advanced alloys. This opens up a range of possibilities in design and manufacturing.

In the metallurgical industry, precision and quality are crucial. CNC machining tools represent the core of excellence in the manufacturing of metal components, enabling the creation of complex parts with unparalleled precision. By connecting this article with “Chip Removal Machining in the CNC Era,” we can explore how these tools are essential for optimizing efficiency and quality in the metallurgical industry, ensuring products of the highest quality.

Continuous Innovation with CNC Machining Tools

Current Trends in the Metallurgical Industry

Innovation is an endless journey. At Asimer Group, we stay at the forefront of current trends in the metallurgical industry. The integration of advanced Industry 4.0 technologies in the machining process is revolutionizing efficiency and precision, pushing manufacturing towards new frontiers of innovation and automation.

Sustainable Development

Sustainability is a growing concern in the industry. Asimer Group’s CNC machining tools are designed not only to provide precision and efficiency but also to minimize waste and reduce environmental impact. This vision towards a sustainable future reflects our commitment to corporate social responsibility.

But how does this vision translate into practice? Dive into the Transformation of Pump and Valve Manufacturing with the Detailed Applications of CNC Machining. In the world of the metallurgical industry, these tools are not just instruments; they are the driving force of excellence, taking pump and valve manufacturing to new heights. CNC machining redefines every aspect of this process, from millimeter precision to limitless customization. Join us on this journey where computerized control becomes the indispensable ally, transforming pump and valve manufacturing into a masterpiece of innovation and efficiency.

Metrology and Quality Inspection Room: The Guarantee of Excellence

At the core of the metallurgical industry, where every tiny millimeter counts, CNC machining tools emerge as the true creators of excellence. In this environment, the metrology and quality inspection room become an essential element for Asimer Group. In this specialized space, every millimeter gains significance, and precision takes on the leading role. Here, our commitment to quality reaches higher levels, using measurement instruments like the measurement arm to ensure that each component manufactured by CNC machining meets the most demanding tolerances. This room is not just a physical place; it represents the epicenter where meticulousness and excellence converge, ensuring that every product leaving our facilities complies with the strictest quality standards in the metallurgical industry. At Asimer Group, the metrology and quality inspection room are more than a space; they are the guarantee of precision and quality that will determine customer satisfaction and strengthen our position as leaders in precision manufacturing.

The Future of Asimer Group with CNC Machining Tools

Excellence in Every Detail

For Asimer Group, each project is an opportunity to demonstrate excellence in every detail. With CNC machining tools, we are committed to exceeding expectations and setting higher standards in the metallurgical industry. Continuous investment in advanced technologies places us in the ideal position to face future challenges and deliver solutions of exceptional engineering quality.

CNC Machining for Diverse Industries

Asimer Group, a leader in the world of CNC machining, goes beyond expectations in key sectors such as oil and gas, naval, paper pulp production, petrochemical industry, cryogenics, desalination, and water and wastewater management.

In the competitive oil and gas sector, Asimer Group deploys accuracy CNC machining tools to the millimeter, ensuring efficiency in challenging environments. In the naval sphere, our CNC milling machines and lathes are essential allies, providing solutions tailored to the complexity of shipbuilding.

Within the paper pulp production, Asimer Group’s CNC machining redefines standards with its versatility, providing innovative solutions. In the petrochemical industry, we set the pace with advanced solutions addressing unique challenges.

Our CNC machining tools also shine in the fascinating world of cryogenics, where extreme tolerances are essential. Additionally, we tackle the crucial task of desalination, contributing to the sustainable supply of drinking water worldwide.

Asimer Group’s commitment to sustainability is reflected in the efficient and responsible management of water and wastewater, where our tools not only meet rigorous standards but also contribute to conscious water resource management.

As a leader in CNC machining, Asimer Group presents itself as the ideal partner for various industries, driving innovation and excellence in every project.

With state-of-the-art tools, we are prepared to face present and future challenges in these key industries.

Conclusion: The Key to Success in the Metallurgical Industry

In conclusion, CNC machining tools are the essence of excellence in the metallurgical industry. At the heart of Asimer Group, these tools are not just instruments; they are allies in our mission to deliver quality products and cutting-edge engineering solutions. The precision and efficiency provided by these tools not only define our brand but also contribute to the continuous advancement of the metallurgical industry. In a world where innovation and quality are imperatives, Asimer Group stands out as a leader that finds in CNC machining tools the key to lasting success in the manufacturing of industrial pumps and valves.